When sketching for this project, I tried to really focus on the idea of continuity and rounded form. I was particularly intrigued by the path of connected modules (in the rounded arms), as you can se in the sketches above. I thought this was a simple, yet elegant way to maintain an organic shape, with a different approach to the execution of voids throughout the piece.

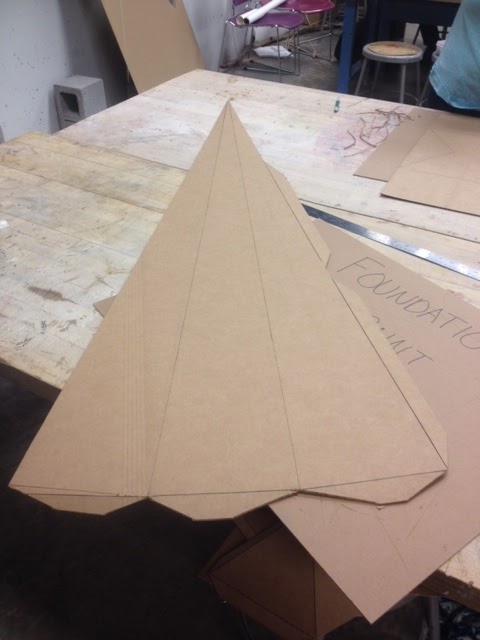

Building the wire armature for the piece was not as difficult as I thought it would, especially since my form had a very generalized overall interior outline. I basically attached three large rings to the circular base, as well as to each other. From there, I cut the burlap out, soaked it in liquified plaster, then placed it around the wire structure, to give the piece a solid foundation to work from. I started at the base and worked my way up to maintain stability and balance.

Once the burlap was place, I added "putty" staged plaster on top of it. I made the base layer very thick to maintain an obvious base to the arms of the piece. I was not yet concerned with smoothing out the form as much as just getting the overall shape in place to work from.

When the base was plastered, I then added the putty plaster to the arms, trying to maintain a consistent thickness through out each. I wanted the base of each arm to be thicker, and then the arm would slightly and gradually thin out as the arm extended towards the next arm. A final layer of putty was used to smooth out the form as much as I could.

Finally, after all the plaster was added, came time for sanding to smooth out any rough patches. This proved much more difficult and time consuming then I thought it would be. I used first a medium grade sand paper, then tried to refine with a finer grade. I ran into the issue of air pockets--so many air pockets. I assume this occurred when I applied runnier states of plaster during the putty construction stage of the process, trying to smooth out the form as I waited for the plaster to thicken. I later learned after many layers of doing this that this was no the smartest thing to do, because it, indeed, cause air pockets. So I reached a point in sanding wear the more I tried to smooth down some places, I was opening up the air pockets in other places. Eventually I had to stop or i knew I would just keep sanding until I reached burlap or the form lost its intended thickness.

Overall, I was kind of "eh" about this project. I really liked how quick the plaster dried while constructing because it was then easier to keeping building on top of. However, I felt like so much time was wasted just waiting for the plaster to reach the putty stage to actually begin construction. I also didn't like sanding; I hated the feeling of powder all over myself and my hands, and there were times i rubbed my fingers raw trying to get a grip on the sand paper. It was difficult to smooth out some curvaceous spots because of their significant angle in curvature. I think I had a pretty solid idea initially, and did alright in my first go with plaster, but looking back now, I can definitely fix mistakes I made in this project if I were to do it again. My craft could have been a lot better in all honesty; air pockets were my enemy and their came a point where I couldn't really do anything to fix them, but just try to roll with it. I tried to stick to my original sketches, however the piece did not come out as symmetrical as I wanted it to be, which also ties into my craft. And my final form was very heavy, which was a real pain trying to transport; and the dust from the plaster gets everywhere! Honestly, Im kind of glad I'm done with this project.